Manufacture strip lashes are a delicate process that requires time and patience to master. It can be difficult for someone who has never done it before, but the result will be well worth it.

The structure of strip lashes seems simple, but they still have a 10-step process. There are two ways of making mink lashes. One is to make them by hand, and the other is to make them with a machine. Manufacturers will often use a combination of hand and machine production methods to meet high demand. They may also try different materials for their lashes bases. It is all dependent on which is more cost-effective at the time.

Do you want to learn how to make or manufacture strip lashes? You’re in luck. Here is a quick guide on how manufacturers make false strip eyelashes.

With all the steps to create a set of strip lashes, it’s no wonder that these false eyelashes take time and effort.

1. Put Each Hair On A-Line

The first step is making the first shape of eyelashes.

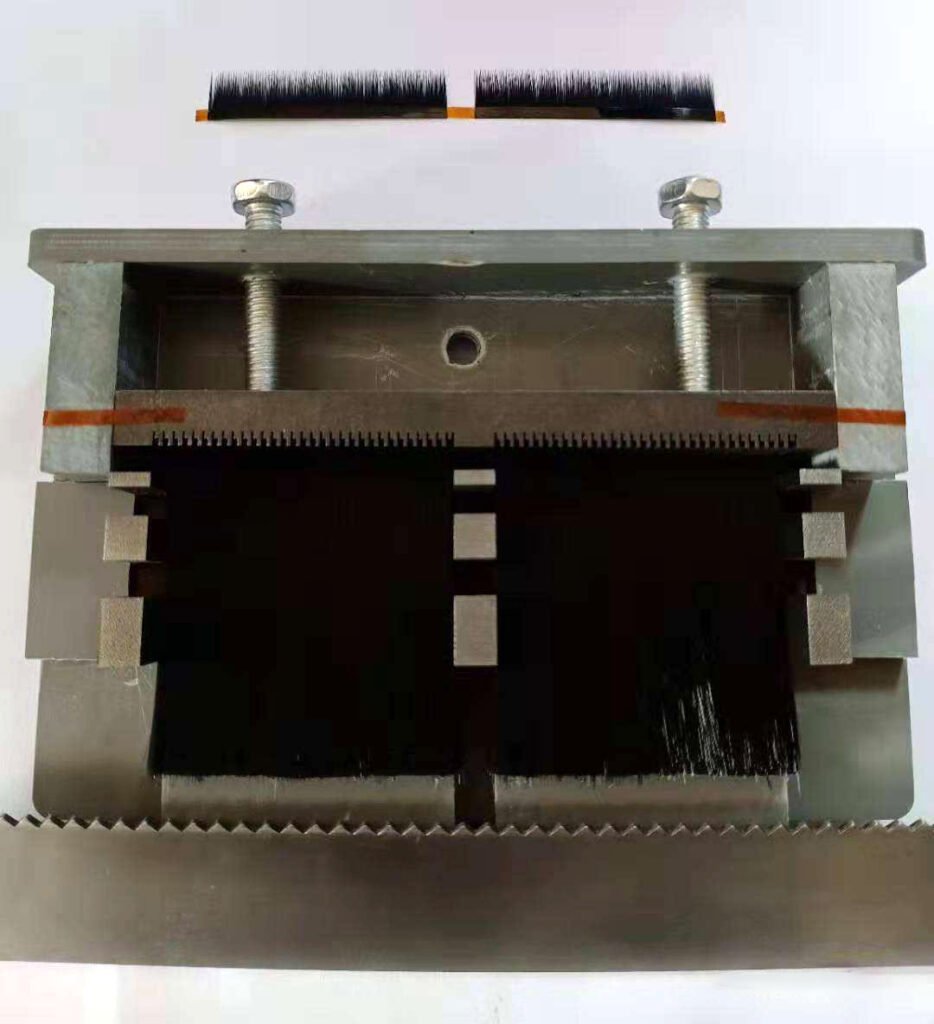

There are 2 kinds. One is all by humans, One is by mold.

Most of them are put the hair materials into a mold, Then use the double-sided adhesive to stick the hairs in a line. It creates an initial shape for your lash line.

It is where low-quality hairs are being removed (curved hair). Workers delicately choose soft and smooth hair.

Then, workers can change it as needed by adding more or removing some of it.

After lining the hairs, one layer of eyelashes is finished. Carding various forms is the goal of this operation. To prepare for the following growth phases, we need to match the hair type to the shape. The hair has both vertical and oblique orientations.

The worker’s eye is an instrument that can determine whether a particular hairstyle will work for the next steps. This step requires careful consideration to build up precisely what you want and need at this point.

Making sure the right shape and height is the critical part.

2. Combined The Lined Hairs Together

Next, they combine each layer of lined hairs together

At this stage, workers should gently put lined hairs onto other lined hairs and stick them together with double-sided adhesives they already have. Then, they press them to make sure they are stick tight.

Ensure that the top and bottom of each double-sided tape overlap。

And make sure the gap between each pair of lashes and lashes is even.

The steps affect the quality of false eyelashes. They can create a mess with the volume, curl, and definition of false eyelashes.

This process requires great care and patience. Sometimes, it requires workers to have rich experiences to finish the step.

3. Stick Cotton Band And Hairs Together

Put the cotton band on the desk, and put the combined hairs on the cotton band.

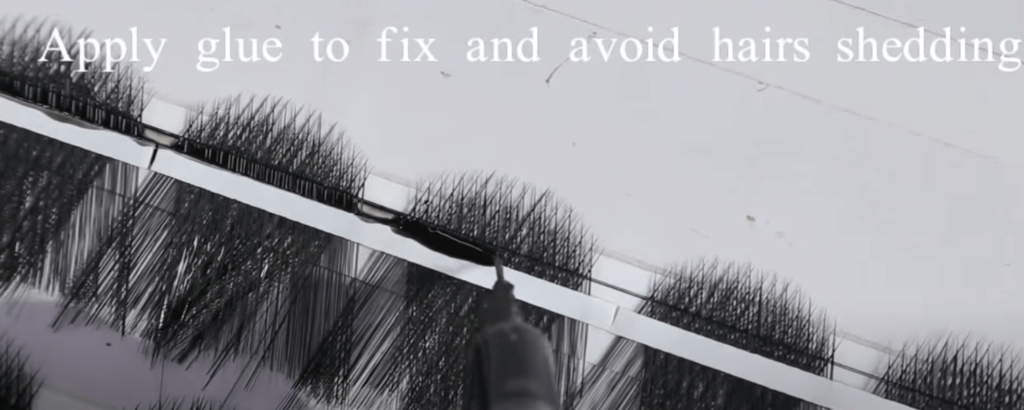

The worker fills black glue on a needle, fills glue between the eyelash band and the double-sided tape by the needle.

Check the glue softness and penetration is the critical point. If the glue is not penetration enough, the hair will easily fall out when used

4. Cut off The Extra Hair

The hair removal process is where the excess, unwanted hairs are cut off.

Eyelashes are cut with thick blades. It is typically an Artwork knife, but it depends on the type of eyelash you’re removing.

Each style pair of lashes will cut off 30% of the hair material. It also establishes the basic form.

5+6. Roll Eyelash And Adjust The Eyelash Shape

Put the primary form of eyelashes on special paper. Wet the paper.

Start to Roll the eyelashes.

After the eyelashes are rolled up, each glass tube is bundled together. Then, they are placed in a steamer or oven for heating to create curls. Different thicknesses of tubes need to be used depending on what customers want. But it also varies from person-to-person requirements, so there’s no set rule.

These beautiful eyelashes are applied by using the most expensive glue on the market. They use this magical potion to make sure that your eyes will be puffy and perfect for hours once they’re done.

The most important thing to remember is to use tweezers to adjust an eyelash. You want it straight and even a line of separation from your lashes. So if there are any stray hairs or lumps in their current shape, they can easily get caught by the tweezers. Here are ways why this step is essential:

- To strictly divide the shape.

- To avoid messing with the hair.

- To avoid stray hair.

- To ensure that the shape is stable.

The false eyelash is then processed on the heating tube with the eyelashes and paper together to circle into a tube, fixed. It’s the legwork that goes into achieving a beautiful curl.

7. Heat The Eyelash Styling

Put the tube in the oven.

Curling eyelashes at high temperatures is a common way to create a degree of curl. Eyelash curlers should be used when you want your eye makeup to last longer. It also helps users stand out more in contrast with natural lash line movement. Sometimes, even without wearing any mascara altogether.

The heat from an iron will give lashes their desired shape. It is through melting away unwanted length while still maintaining its original thickness. They are also giving them a much better definition.

The most common way for manufacturers to get eyelashes ready is through steaming. It is a method that uses moist heat. The steam produced by boiling water in a closed vessel generates moist heat.

Yet, some manufacturers use the stove for steaming. The stove in this process will be used, and it’s from firewood. It means each batch of lashes has its own unique healing time. Not all stoves work at the same rate or temperature.

Our manufacturing process uses the most up-to-date equipment and techniques. In turn, it maximizes our workforce’s productivity. To do a profitable business, you need to have enough space and time. You also need to keep the temperature stable and use scientific management.

8+9. Glue-On Eyelash Band/stalk/stems

After the eyelashes are second glued and steamed out for a fixed time, put the curled eyelash onto a board, Then put them in sunlight. Let them naturally dry

Full-time workers are on hand to ensure that the drying process is conducted correctly, with 360-degree coverage all around. For this reason, it’s vital to dry by natural airflow. There can be mistakes or oversights when people aren’t constantly checking their work as they go along. It could result in spoilage of product quality.

10. Packaging On Tray

The process of putting on the eyelashes on trays is also called “on stage.”

Workers will tear the sun-dried lashes off (with a specific viscosity). Then, they will put them onto an individual tray to complete production.

Conclusion

If you’re looking to sell false eyelashes, one way to be professional sell is to know how they are made. There is no need to be concerned about the safety of your eyes when buying them. Manufacturers go through rigorous testing before they can sell their products.